Gaylord Boxes

Guides, FAQs, and Buyer Tips on Gaylord Boxes for Industrial Use

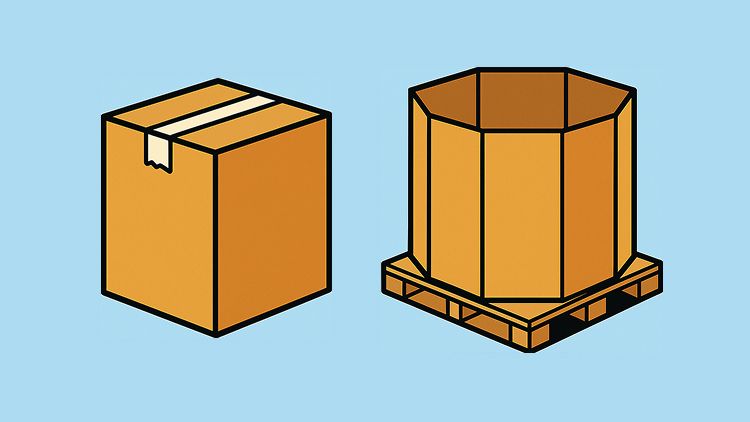

Short answer: Use an RSC (regular slotted container) for case-packed, parcel-friendly shipments; opt for a pallet-sized bulk bin (often called a “Gaylord”) for heavy, loose, or consolidated product that moves by forklift.

In the world of packaging procurement, terms like pallet box, Gaylord box, octabin, and bulk bin often overlap, leading to confusion. This guide provides an authoritative breakdown based on industry standards, historical context, and technical insights to help you navigate these distinctions effectively.

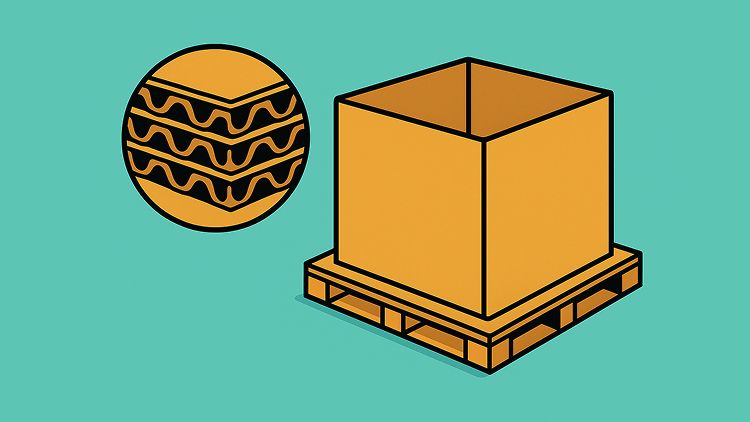

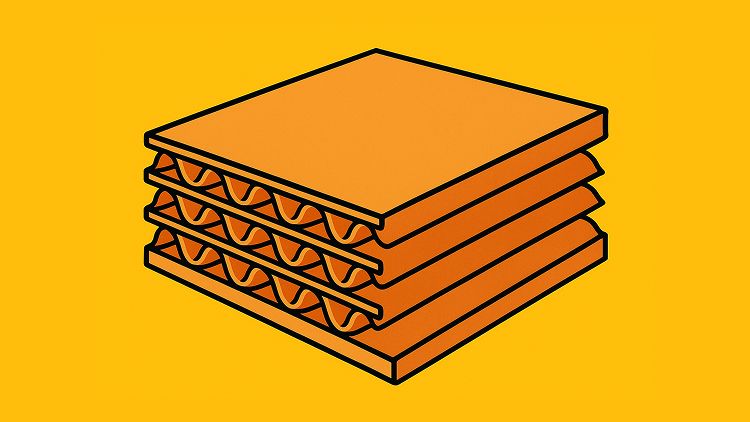

In industrial packaging, tri-wall boxes — also called triple wall Gaylord containers — set the standard for durability, compression strength, and sustainability. Constructed with three layers of corrugated fluting (seven-ply total structure), these Gaylord boxes are engineered to support heavy loads up to 2,000 lbs, making them essential in manufacturing, defense, and logistics sectors.

From our experience, Gaylords are corrugated, heavy-duty, reusable bulk bins for real load-bearing. A bulk cargo container can technically be a Gaylord, but most boxes sold as “bulk cargo containers” are lighter capacity and intended for single use. Similarly, many bulk cargo bins with a pallet-sized footprint are described as “Gaylords,” but lack the weight capacity and bulge resistance of a true Gaylord box

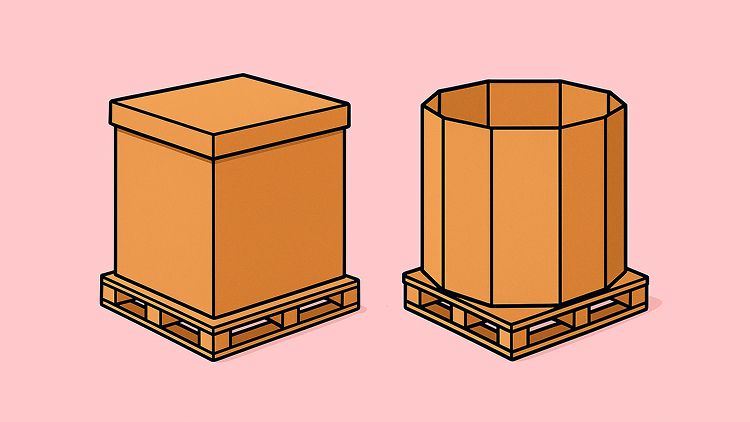

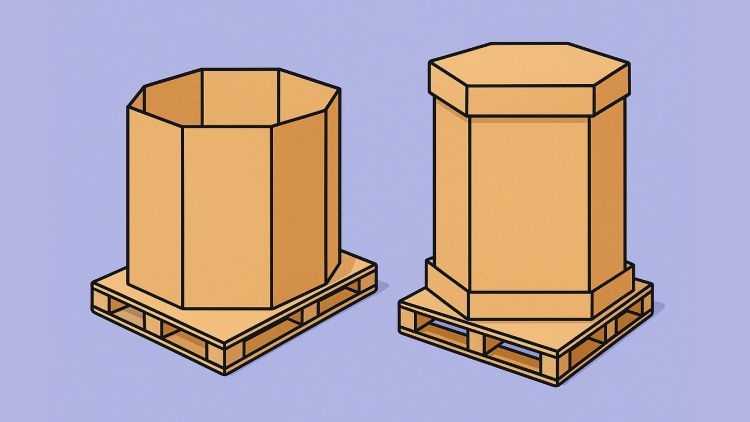

When shipping goods in bulk, the terms "Gaylord box" and "Octabin" are often used, but they aren't always interchangeable. While both are heavy-duty containers designed for pallet-sized loads, the octabin offers specialized advantages for specific applications. This guide will clarify the meaning, features, and key differences to help you choose the right packaging.

Pumpkin Bins can be plentiful before Halloween, then tighten quickly. After October 31, surplus consolidates at wholesalers while retail demand pivots to pies and baking. The window is short. Prioritize speed, clear specs, and flexible freight. For storage do’s and don’ts (temperature, humidity, and handling), lean on research-backed guides like UC Davis Postharvest (pumpkin & winter squash) and the USDA ARS Commercial Storage manual.

Not all Gaylord boxes are built the same—and wall count is one of the biggest factors that determines how they perform. Whether you’re shipping lightweight recyclables or dense industrial materials, the number of walls directly affects how much weight a box can carry, how many times it can be reused, and how well it stacks in storage or transit.

Whether you’re selling or buying Gaylord boxes for bulk storage, one of the most common questions is about cost. Prices vary between new and used boxes, and within those groups, specialty designs like produce bins or HPT-41 models may shift the range. Here’s a breakdown of what to expect when it comes to cost and value.

If your warehouse or facility has a surplus of Gaylord boxes, you don’t have to let them go to waste. Instead of paying for disposal or recycling, you can sell them. At Verde Trader, we buy Gaylord boxes directly from businesses, making the process simple and efficient.

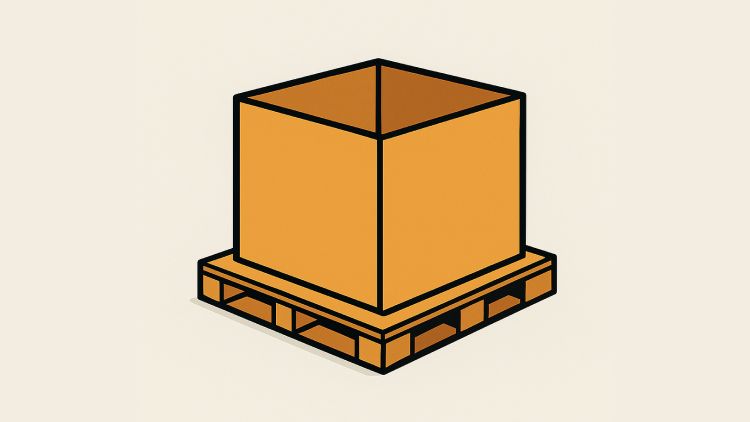

If you work in manufacturing, recycling, food processing, or large-scale distribution, chances are you’ve come across the term Gaylord box. But what does “Gaylord” mean, why are they called that, and where can you buy them? This guide answers those questions and highlights the role Gaylord boxes play in industrial packaging.

Gaylord box dimensions refer to length × width × height of a bulk corrugated container built to sit on a pallet. In North America, 48" × 40" is the most common footprint; height is selected for the job at hand. The key is to match interior space to your product and handling method, then confirm that the full outside dimensions fit your aisles, racks, and trucks.