Why Wall Count Matters When Choosing Gaylord Boxes

Understanding how box construction impacts performance, cost, and safety in storage and shipping.

Key takeaways

- Wall count determines a box’s load capacity, stacking strength, and reuse potential.

- 3-wall and 5-wall boxes are the most common choices for industrial and recycling applications.

- Matching wall count to your material type helps optimize cost, safety, and efficiency.

Not all Gaylord boxes are built the same—and wall count is one of the biggest factors that determines how they perform. Whether you’re shipping lightweight recyclables or dense industrial materials, the number of walls directly affects how much weight a box can carry, how many times it can be reused, and how well it stacks in storage or transit.

What wall count means

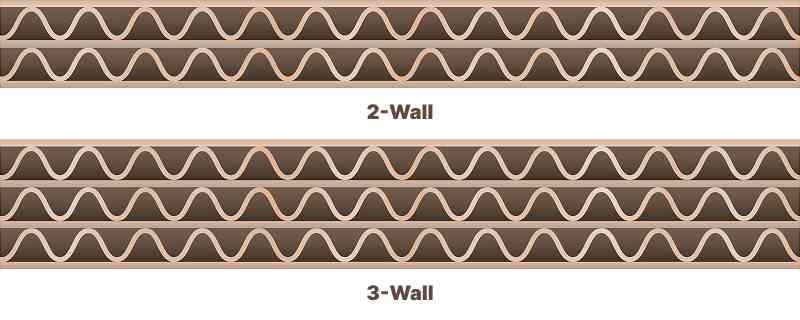

“Wall count” refers to the number of corrugated layers used to form a Gaylord box’s sides. Each wall layer combines flat paperboard liners and fluted (wavy) inner sheets that increase rigidity and crush resistance.

Common wall types include:

- 2-Wall: Designed for lighter, non-abrasive contents such as textiles, small parts, or loose recyclables.

- 3-Wall: A mid-strength option for moderate-weight materials like plastics, rubber, or dry goods.

- 4-Wall: Offers heavy-duty protection, ideal for bulk powders, components, or heavier commodities.

- 5-Wall: Maximum durability for industrial, agricultural, or high-density products such as resins and scrap.

How wall count impacts performance

Choosing the right wall strength is about balancing durability and efficiency.

- Weight capacity: A 2-wall box may safely hold 600–800 lbs, while a 5-wall box can exceed 1,500 lbs.

- Stacking strength: Taller stacks and tighter storage spaces benefit from thicker walls that resist crush.

- Reuse life: Higher wall counts better withstand forklift handling, moisture, and multiple reuse cycles.

Even when reused, Gaylord boxes with higher wall counts maintain better structure over time—making them a smart investment for operations that handle bulk material frequently.

Condition and construction details to check

When comparing listings, wall count should be your first filter—but not your only one.

Pay attention to:

- Box shape: Octagonal boxes offer stronger corners and more even stacking pressure.

- Bottom style: Partial or full flaps affect load stability; domelock bottoms resist bulging.

- Material grade: Kraft liners and reinforced fluting add strength and moisture resistance.

- Dimensions: Standard 48×40 footprints fit most pallets, with height ranging from 36–46 inches.

Typical pricing by wall count

| Wall Count | Typical Applications | Price Range (Used) | Price Range (New) |

|---|---|---|---|

| 2-Wall | Lightweight items, textiles, plastics | $6 – $10 | $14 – $18 |

| 3-Wall | Recyclables, bulk materials | $8 – $14 | $16 – $20 |

| 4-Wall | Industrial parts, heavy goods | $10 – $17 | $18 – $24 |

| 5-Wall | Scrap, resins, produce, dense loads | $12 – $20 | $22 – $28 |

Conclusion

Understanding Gaylord box wall strength is key to selecting the right packaging for your operation. From lightweight 2-wall containers to 5-wall heavy-duty boxes, each design serves a purpose. When in doubt, start with your load weight, handling method, and storage environment—then match your wall count accordingly for reliable, cost-effective performance.