The Ultimate Guide to Tri-Wall Boxes and Triple Wall Gaylord Containers

Strength and sustainability in heavy-duty packaging

Key takeaways

- Triple-wall = heavy-duty: Seven-ply (three mediums, four liners) tri-wall boxes deliver far higher ECT and stack compression than double-wall—commonly ~800–2,000 lb load ratings, with durable configurations stacking to ~5,000 lb.

- Built for critical moves: Widely used in manufacturing, defense, and export; many specs align to ASTM D5168 and DoD packaging standards for impact, vibration, and moisture control.

- Choose by structure, not shape: “Gaylord” is the bulk-bin form factor; tri-wall is the wall construction. Octabins may be tri-wall, but not always—use tri-wall for dense/flowable or high-risk loads; lighter bulk cargo boxes suit one-way, lower-weight shipments.

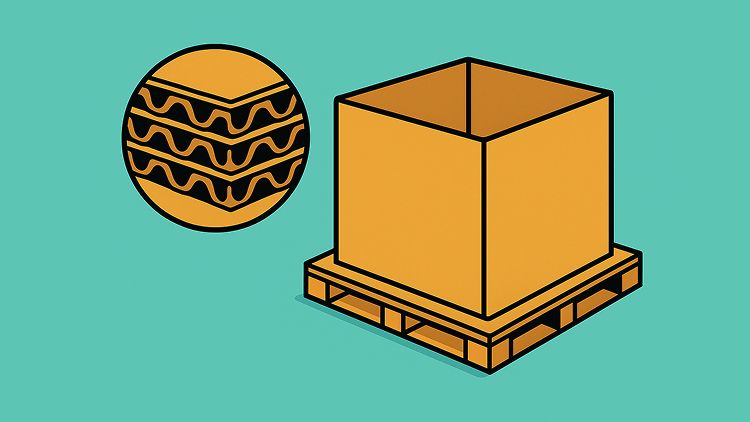

In industrial packaging, tri-wall boxes — also called triple wall Gaylord containers — set the standard for durability, compression strength, and sustainability. Constructed with three layers of corrugated fluting (seven-ply total structure), these Gaylord boxes are engineered to support heavy loads up to 2,000 lbs, making them essential in manufacturing, defense, and logistics sectors.

According to Global Market Insights (2024), the corrugated bulk-bins market was valued at USD 14.2 billion in 2023 and is projected to exceed USD 19 billion by 2032 (CAGR ~5%), driven by demand for recyclable heavy-duty containers. Triple-wall Gaylord boxes dominate this segment, with applications in resins, automotive components, produce, and aerospace parts — where failure is not an option.

What is a tri-wall box?

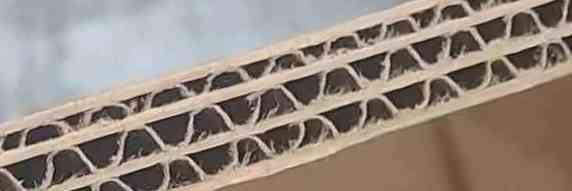

A tri-wall box (or triple wall corrugated box) consists of three corrugated mediums and four linerboards bonded with starch adhesives, forming a seven-ply structure. This configuration significantly increases edge-crush strength (ECT) and stack compression capacity, outperforming double-wall fiberboard by up to 2.5× under controlled conditions (study on the Mechanical Properties and Behavior of Corrugated Cardboard under Tensile and Compression Loads, ResearchGate, 2023).

In U.S. manufacturing and defense logistics, tri-wall Gaylord containers conform to ASTM D5168 and Department of Defense packaging standards (Lockheed Martin Space Systems Packaging Specification, 2023), ensuring impact resistance, vibration tolerance, and moisture protection.

Learn more about their history and modern applications: What Are Gaylord Boxes.

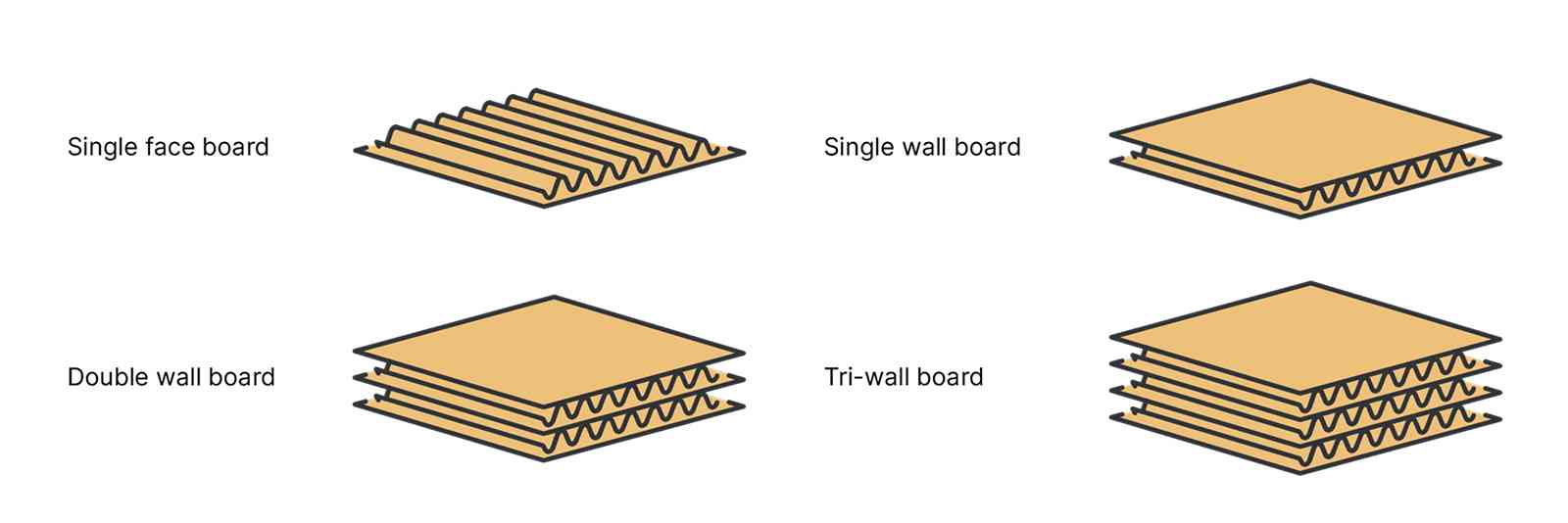

Tri-wall containers vs. standard corrugated boxes

| Corrugated Grade | Structure | Typical Weight Capacity | Primary Applications |

|---|---|---|---|

| Single Wall | 1 fluted medium (3 plies) | Up to 65 lbs | Retail & consumer goods |

| Double Wall | 2 fluted mediums (5 plies) | Up to 120 lbs | Moderate industrial loads |

| Tri-Wall | 3 fluted mediums (7 plies) | 800 – 2,000 lbs | Heavy-duty shipping, defense, export pallets |

A triple-wall corrugated box delivers up to 5,000 lbs of stacked compression strength in durable configurations (Solus Group: Gaylord Boxes Features, Handling, and History, 2024).

Compare with lighter alternatives: Bulk Cargo Containers vs. Gaylord Boxes.

Gaylord containers and their industrial role

The term “Gaylord container” originated from the Gaylord Container Company in the 1920s and now generically describes large, palletized bulk corrugated boxes used for recyclables, resin pellets, raw materials, and industrial waste (Solus Group, 2024). When constructed with three-wall corrugated material, they become triple-wall Gaylord boxes — capable of supporting up to 5,000 lbs in high-performance models.

Browse our full selection: Gaylord Boxes.

Tri-wall and Gaylord box dimensions

Note: Volume calculated using internal dimensions (wall thickness ~1–1.5" per side). Load ratings based on standard configurations (Uline 1,100# Triple Wall Boxes Catalog, DLA Form 3507, 2023). Always verify with the supplier.

Need precise sizing? See our Gaylord Box Dimensions Guide.

| Container Type | Internal Dimensions (in.); Volume (cu ft) | Material | Recommended Load |

|---|---|---|---|

| Standard Tri-Wall Gaylord | 46 × 38 × 36; 36.3 | Triple wall corrugated | 1,000–2,000 lbs |

| Heavy-Duty Tri-Wall | 48 × 40 × 36; 40.0 | Triple wall corrugated | 2,000–3,000 lbs |

| Military Tri-Wall | 45 × 45 × 50; 58.6 | Triple wall fiberboard | 1,500–2,600 lbs |

Popular tri-wall box options & Uline standards

| Dimensions (L × W × H) | Test Rating | Max Load |

|---|---|---|

| 48 × 40 × 36 | 1,100# TW | 1,200 lbs |

| 48 × 40 × 48 | 1,100# TW | 1,200 lbs |

| 60 × 48 × 40 | 1,100# TW | 1,200 lbs |

What does “1,100# TW” mean?

“1,100# TW” means 1,100-lb-test triple-wall corrugated per ASTM D781 and TAPPI T810 standards — engineered for dense freight, metals, resins, and heavy-duty Gaylord box applications.

Most Popular Size: 48 × 40 × 36 to 40 — fits standard GMA pallets, maximizes 40 cu ft internal volume, and supports 1,200+ lbs safely in triple-wall construction.

Are octabins tri-wall boxes?

Many octabins — eight-sided bulk containers — are constructed with triple-wall corrugated board, delivering mechanical performance equivalent to tri-wall Gaylord boxes (Laminations Online: Understanding Gaylord Boxes Comprehensive Alternative Guide, October 2025).

However, “octabin” refers to shape, while “tri-wall” defines wall structure (three corrugated mediums). Thus, some octabins are tri-wall, but not all.

Decide which fits your needs: Gaylord or Octabin.

Bulk cargo bins vs. tri-wall boxes: choosing the right container

| Feature | Bulk Cargo Bins | Tri-Wall Boxes Gaylord Boxes |

|---|---|---|

| Typical capacity | Light–moderate (≤ 500 lbs) | Heavy (800 – 5,000 lbs) |

| Wall construction | Single / Double Wall | Triple Wall |

| Ideal use | Irregular loads, low-cost shipping | Industrial, export, military |

| Strength & stacking | Moderate | High (up to 5,000 lbs stacked) |

| Compliance | General shipping | ASTM D5168 / DoD standards |

Full comparison: Bulk Cargo Containers vs. Gaylord Boxes

Handling and warehouse safety

Follow these OSHA-aligned best practices when handling Gaylord boxes (Solus Group: Handling Gaylord Shipping Boxes at the Warehouse – 4 Safety Tips, 2024):

Military and aerospace applications

Triple-wall Gaylord boxes meet ASTM D5168 and DoD 3507 standards for munitions, electronics, and satellite components, widely used in defense logistics (Lockheed Martin Space Systems Packaging Specification, 2023).

Environmental and economic advantages

With a 93.1% recycling rate for corrugated materials in 2023 (American Forest & Paper Association (AF&PA), 2024), Gaylord boxes support closed-loop sustainability. Manufacturers like Tri-Wall Group achieve up to 30% waste reduction through reuse and recycling programs.

Conclusion: industrial reliability built into every wall

From bulk cargo bins to triple-wall Gaylord containers, tri-wall technology delivers superior load-bearing capacity, stacking safety, and eco-efficiency for modern industrial logistics.

References

- Global Market Insights (2024)Corrugated Bulk Bins Market Size, Share & Trends Analysis Report – Market valued at USD 14.2B in 2023, projected to exceed USD 19B by 2032.

- ResearchGate (2023)Study on the Mechanical Properties and Behavior of Corrugated Cardboard under Tensile and Compression Loads – Triple-wall outperforms double-wall by up to 2.5× in compression.

- ASTM D5168Standard Specification for Triple Wall Corrugated Fiberboard – Compliance for military and industrial tri-wall boxes.

- Lockheed Martin Space Systems Packaging Specification (2023)Supplier Packaging Requirements – Specifies ASTM D5168 triple-wall for aerospace and defense.

- Solus Group (2024)Gaylord Boxes: Features, Handling, and History – Origin of Gaylord name, up to 5,000 lbs capacity in triple-wall.

- Uline 1,100# Triple-Wall Boxes CatalogProduct catalog – Models S-16782, S-19051, S-20132 with dimensions and 1,200 lbs load ratings.

- DLA Form 3507 (2023)Defense Logistics Agency packaging standard – Military tri-wall specifications.

- ASTM D781Standard Specification for Triple Wall Corrugated Fiberboard Containers – Defines 1,100# test rating.

- Laminations Online (October 2025)Understanding Gaylord Boxes: Comprehensive Alternative Guide – Octabins often use triple-wall construction.

- Solus Group (2024)Handling Gaylord Shipping Boxes at the Warehouse – 4 Safety Tips – OSHA-aligned handling guidelines.

- AF&PA (2024)U.S. Corrugated Recovery Rate Reaches 93.1 Percent in 2023 – Industry recycling statistics.