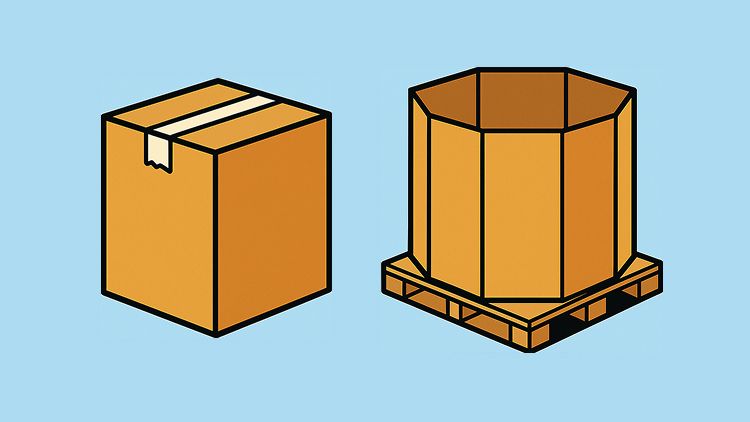

RSC vs. “Gaylord” (Bulk Bin): Which Corrugated Workhorse Fits Your Load?

Written by

The Verde Trader Team

Subtitle

Published February 16, 2026

Key takeaways

- Form factor decides: Use RSC for case-packed parcels; use a pallet-size Gaylord/bulk bin for heavy, loose, forklift-moved product.

- Strength scales up: RSCs are single/double-wall; Gaylords can be double/triple/laminated for much higher loads.

- Real-world limits vary: Pallet stiffness, ECT/BCT, humidity, and box geometry determine stacking performance.

Short answer: Use an RSC (regular slotted container) for case-packed, parcel-friendly shipments; opt for a pallet-sized bulk bin (often called a “Gaylord”) for heavy, loose, or consolidated product that moves by forklift.

At a Glance

- RSC (Regular Slotted Container): The most common shipper case, with all major flaps of equal length meeting at the center for quick sealing. For a detailed overview, check out NC State Extension’s guide on produce packaging which highlights the prevalence of RSCs, and a Virginia Tech thesis that defines RSC as FEFCO 0201 with center-meeting flaps.

- Gaylord / Bulk Bin: A pallet-sized corrugated bin (square or octagonal) used for bulk produce, parts, or e-waste. Universities often refer to these as bulk bins in academic contexts, but the term Gaylord is common in campus operations, as noted in UF/IFAS EDIS and UT Knoxville EHS guidelines.

Definitions & Where Each One Shines

What is an RSC?

An RSC is the standard corrugated case style with outer flaps meeting at the center, allowing for fast tape sealing and compatibility with automated packing. It’s the go-to shipper carton across industries. For a deeper dive into its fundamentals, explore NC State Extension’s discussion on produce packaging which notes RSC as the most popular choice, and Virginia Tech’s reference confirming RSC as FEFCO 0201 with equal-length flaps.

Best for: Case-packed items, parcel networks, and palletized cases manageable by hand.

What is a “Gaylord” (Bulk Bin)?

In academic and extension literature, you’ll often see terms like bulk bin or octabin, but in everyday operations, many call it a “Gaylord”—a pallet-sized corrugated bin moved by forklift or pallet jack. For practical insights, refer to UF/IFAS guidance on postharvest storage and packaging which details bulk bins for produce, and UT Knoxville EHS which uses Gaylord for palletized e-waste collection on campus.

Best for: Heavy, loose, or irregular products; quick bulk moves; line-side replenishment; returns consolidation; and field-to-cooler produce handling.

Strength, Walls & Real-World Limits

- Wall Constructions: RSC shipper cases are typically single- or double-wall, while bulk bins can go up to double-, triple-, and laminated multi-wall for heavier loads. Learn more about wall types and compression impacts from Georgia Tech/IPST’s research on ECT/BCT and Cascades’ overview of bin wall options.

- Capacities: Heavy-duty laminated bulk bins are rated up to ~3,000 lb by manufacturers like International Paper, which also highlights superior top-to-bottom compression in laminated designs. Note that this is a supplier spec, not a universal standard.

- Stacking Performance: Octagonal bulk bins (octabins) resist bulging and perform well under vertical stacking, as explored in a 2021 MDPI study on octabin mechanics.

- Environment Matters: Compression strength isn’t static—humidity and moisture can reduce box strength, influenced by ECT (edge crush) and geometry (McKee relationship). Dive into Georgia Tech/IPST’s notes on ECT to BCT conversion and their analysis of moisture effects on BCT.

- Unit-Load Interface: Pallet stiffness, packaging size, and containment affect box compression, a recurring theme in Virginia Tech CPULD theses which explain why “same grade” boxes behave differently once unitized.

Pallets, Handling & Cube

- In U.S. grocery and CPG supply chains, the 48 × 40 in (GMA) pallet is the standard, so bin and case footprints are designed around it. See more on GMA dimensions in NC State Extension’s packaging notes.

- Handling: RSCs are ideal as handable cases for parcel carriers or palletized case packs, while bulk bins are built for forklift moves, often used field-side, plant-side, or in reverse logistics like electronics recovery. Check out UF/IFAS on bulk bins for produce and UT Knoxville on Gaylords in campus e-waste operations.

RSC vs. Gaylord (Bulk Bin): Side-by-Side

| Feature | RSC (Regular Slotted Container) | Gaylord / Bulk Bin |

|---|---|---|

| Form Factor | Case/carton; many SKUs & sizes | Pallet-sized bin (square or octagonal) |

| Typical Walls | Single- or double-wall | Double-, triple-, or laminated multi-wall |

| Load Type | Discrete items, case-packed | Heavy, loose or consolidated product (produce, parts, scrap, e-waste) |

| Handling | Hand carry, conveyors, parcel; palletize by cases | Forklift/pallet-jack only; palletized by default |

| Stacking | Depends on ECT/BCT, pallet stiffness, humidityDepends on ECT/BCT, pallet stiffness, humidity | Octabins and laminated builds improve stacking & bulge control |

| Capacity (Indicative) | Varies widely by grade/size/conditions | Manufacturer ratings to ~3,000 lb (laminated) |

| Best Fit | E-commerce, retail replenishment, case shipping | Field/plant bulk, kitting, returns, ingredients, produce |

Sources: Insights drawn from Georgia Tech on ECT/BCT, UF/IFAS on bulk bins, International Paper on laminated bin capacities, MDPI on octabin mechanics, and Cascades on bulk bin wall types.

Choosing Quickly: A Practical Decision Path

- Is the product loose, irregular, or very heavy as one stream?

- Yes → Go with a Bulk Bin (Gaylord); consider octabin or laminated walls for high stacking or long storage, as detailed by Cascades and MDPI’s octabin analysis.

- No → Choose RSC cases with suitable ECT/BCT for stack height and humidity, verified via McKee-based calculations and testing per Georgia Tech’s compression guide.

- What’s the pallet interface?

- For 48×40 GMA units, align case/bin footprints to avoid overhang and boost stability, as noted in NC State Extension’s GMA pallet discussion.

- Will humidity be elevated (coolers, produce sheds, tropical lanes)?

- Anticipate BCT losses; opt for higher ECTs, add containment, or reduce stack duration, based on Georgia Tech’s moisture impact study.

- Need evidence for a specific setup?

- Lab-test your unit load since pallet stiffness and package geometry affect outcomes, as explored in Virginia Tech CPULD’s research on pallet-package interaction.

Spec Checklist (Copy/Paste into Your RFQ)

- Format: RSC case / Bulk bin (square | octabin)

- Footprint: Compatible with 48×40 GMA or other pallet size

- Board/Walls: Single | Double | Triple | Laminated (bin)

- Target Stack Height & Time: ___ tiers for ___ days at ___ °F/___ %RH

- Performance Target: ECT ___ / Estimated BCT ___ (McKee), overhang 0 in

- Handling: Parcel | Conveyor | Forklift | Pallet jack; rack conditions?

- Environment: Cooler/humid? → Consider moisture impacts and ventilation

- Liners/Inserts: Poly liners for flowables, corner posts for bulge control (bins)

Terminology Note

“Gaylord” is a common industry term for a pallet-sized corrugated bulk bin. Academic and extension sources often use “bulk bin” or “octabin” instead. University operations, such as those at UT Knoxville EHS, also reference “Gaylord” for e-waste collection and shipping.

Executive summary

- Overall verdict: Mostly supported. Core definitions (RSC vs. bulk bin), use cases, and construction types are consistent with university packaging literature and extension materials.

- What’s strongest: RSC definition and prevalence; bulk‑bin (“Gaylord”) use for palletized, loose/heavy product; multi‑wall constructions for bulk bins. 125. (VTechWorks)

- Nuance/caveats: “Gaylord” is industry jargon for pallet‑sized corrugated bulk bins; many .edu sources say “bulk bin” or “octabin,” not “Gaylord.” Capacity “up to ~3,000 lb” derives from manufacturer specs, not a standard. 6. (International Paper)

- Helpful additions: Cite a case study on palletized bulk bins (e.g., fruit), and a peer‑reviewed analysis of octabins under stacking loads. 89. (unitload.vt.edu)

- What to tweak: Where possible, swap vendor links (Uline, International Paper, Cascades) for .edu explanations and add context on board grade tests (ECT/Mullen) when quoting weights.

References

- Quesenberry, C. (2020). The Effect of Pallet Top Deck Stiffness on the Compression Strength of Corrugated Boxes. Virginia Tech (School of Packaging). Accessed 2025‑11‑12. https://vtechworks.lib.vt.edu/bitstream/10919/104965/1/Quesenberry_CB_T_2020.pdf. (VTechWorks)

- NC State Extension (2025). Chapter 9: Produce Packaging. Accessed 2025‑11‑12. https://content.ces.ncsu.edu/introduction-to-the-postharvest-engineering-for-fresh-fruits-and-vegetables/9-produce-packaging. (NC State Extension)

- University of Pittsburgh (n.d.). Packaging Guidelines. Accessed 2025‑11‑12. https://www.pc.pitt.edu/sites/default/files/Packaging_Guidelines.pdf. (Panther Central)

- Wayne State University (OEHS) (n.d.). E‑waste: 4×4 Gaylord box for collection. Accessed 2025‑11‑12. https://research.wayne.edu/oehs/hazardous/e-waste. (research.wayne.edu)

- University of Florida IFAS (2024). HS1270: Postharvest Storage, Packaging, and Handling of Fresh‑Market Fruits and Vegetables. (Bulk bins incl. corrugated fiberboard). Accessed 2025‑11‑12. https://edis.ifas.ufl.edu/publication/HS1270. (Ask IFAS - Powered by EDIS)

- International Paper (2025). Laminated Bulk Bins (up to 3,000 lb). Accessed 2025‑11‑12. https://www.internationalpaper.com/packaging/laminated-bulk-bins. (International Paper)

- Cascades (2025). Corrugated Bulk Bins (single/double/triple/laminated). Accessed 2025‑11‑12. https://www.cascades.com/en/products-services/packaging/protective-packaging/bulk-bins. (Cascades.com)

- Weigel, T. (VT thesis). Modeling the Dynamic Interactions Between Wooden Pallets and Corrugated Containers During Resonance—unit loads of palletized bulk bins (apples/peaches). Accessed 2025‑11‑12. https://www.unitload.vt.edu/.../Weigel%20-%20ETD...pdf. (unitload.vt.edu)

- García et al. (2021). Mechanical Behavior of Corrugated Cardboard Containers and Octabins under Vertical Stacking Loads. Materials 14(9):2392. Accessed 2025‑11‑12. https://www.mdpi.com/1996-1944/14/9/2392. (MDPI)

- Molina‑Montoya, E. (2017). Corrugated boxes: classifications and RSC (code 0201). Virginia Tech. Accessed 2025‑11‑12. https://vtechworks.lib.vt.edu/bitstream/handle/10919/78616/Molina%20Montoya_Eduardo_T_2017.pdf. (VTechWorks)

- Georgia Tech, Renewable Bioproducts Institute (2020). Box Compression for Copy Paper Boxes—McKee context; single/double wall examples. Accessed 2025‑11‑12. https://research.gatech.edu/sites/default/files/rbi/pdfs/The%20Box%20Compression%20for%20Copy%20Paper%20Boxes%20-%20edited%202020.pdf. (Georgia Tech Research)