IBC Totes

Insights and guides on IBC totes for bulk storage, transport, and reuse across industrial applications.

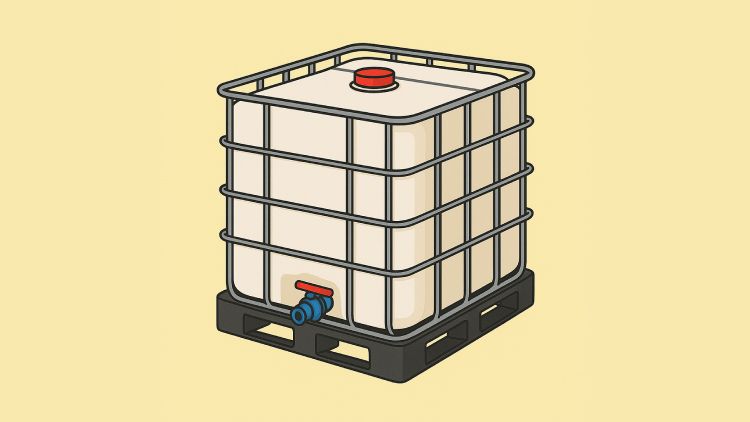

A caged IBC tote, also known as a composite IBC, is built from a blow-molded HDPE bottle held inside a welded steel cage and mounted on a pallet base. Most units hold 275 or 330 gallons and move easily with forklifts. The design protects the bottle, stacks safely, and meets transport standards when properly rated.

Most composite IBCs (275- and 330-gallon) combine: Inner bottle: high-density polyethylene (HDPE) Outer cage: galvanized steel Base: plastic, steel, or wood pallet In recycling, HDPE and steel are the primary targets. Wood bases are usually reused or recycled separately; plastic bases can be recycled with other rigid plastics if the local program accepts them.

1) Specify it right (before the tote is ever filled) Match materials to the product Bottle: HDPE works for many liquids; stainless or specialty polymers may be needed for strong solvents or hot fill. Seals: Choose EPDM (water, mild chemicals), FKM/Viton (oils, fuels, many solvents), or PTFE (broad chemical resistance). Using the wrong elastomer is a slow-motion leak.

When stored outdoors, IBCs (Intermediate Bulk Containers) are exposed to ambient weather. If contents freeze, you risk: Operational delays: contents won’t dispense or pump. Container damage: expansion can crack the inner HDPE bottle, warp the cage/pallet, and split fittings/hoses. Product loss/quality issues: many liquids (e.g., emulsions, certain chemicals) are freeze-sensitive and degrade after a hard freeze.

IBC totes are designed for efficient bulk storage and transport, fitting neatly into standard warehouse racking and truck trailers. Understanding their size and weight is critical for:

Knowing the weight of an empty IBC tote is important for: Shipping logistics – total load calculations for trucks or containers. Warehouse storage – ensuring racks, pallets, or floors can safely support full totes. Handling equipment – forklifts and pallet jacks must be rated to lift filled weights. The weight of the tote is only part of the equation—when filled, a 275-gallon tote of water can weigh over 2,200 pounds, and a 330-gallon tote can weigh more than 2,750 pounds.

IBC totes, short for Intermediate Bulk Containers, are reusable, pallet-mounted containers designed for bulk storage and transport of liquids, semi-solids, and dry goods. They typically come in 275-gallon and 330-gallon capacities, with a plastic HDPE inner bottle encased in a protective steel cage.

The acronym IBC stands for Intermediate Bulk Container. These containers are designed to hold hundreds of gallons of liquids or bulk materials, sitting between small drums and full-size tanker trucks—hence the word “intermediate.” The term “tote” is widely used in the United States to describe the cube-shaped IBC with a plastic HDPE inner bottle, a steel cage for protection, and a pallet base for easy handling.