Caged IBC Tote Anatomy 101

A simple, parts-and-purpose guide to the most common liquid tote on the planet.

Key takeaways

- The tote is a composite design: HDPE bottle + steel cage + pallet base.

- Valves, lids, and markings drive safety, compatibility, and resale value.

- Inspect the bottle, cage, valve, and pallet before reuse or purchase.

A caged IBC tote, also known as a composite IBC, is built from a blow-molded HDPE bottle held inside a welded steel cage and mounted on a pallet base. Most units hold 275 or 330 gallons and move easily with forklifts. The design protects the bottle, stacks safely, and meets transport standards when properly rated.

In short: the plastic bottle stores the liquid, the cage adds strength, and the pallet lets you move it.

Caged IBC tote anatomy (the quick tour)

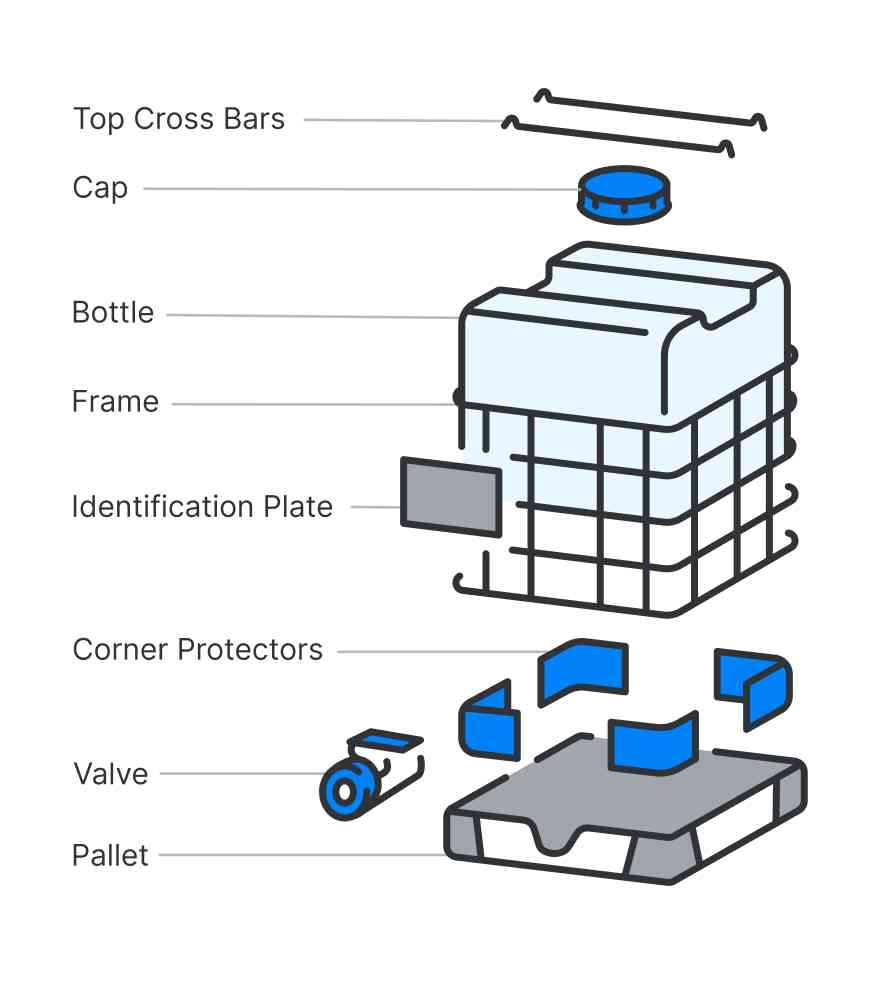

Think of the tote as a few integrated systems—each part has a clear job:

- Inner bottle (HDPE): The primary containment. Opaque or translucent with molded volume marks and date codes. This is what determines liquid chemical compatibility, along with valve/gasket materials.

- Steel cage: A welded grid that protects the bottle and carries stacking loads.

- Top cross bars: Spanning members across the lid area that stiffen the cage, improve stacking stability, and help resist racking during transport.

- Corner protectors: Plastic caps at cage corners that shield the bottle from point loads and abrasion.

- Identification plate (nameplate): A metal plate or stencil panel on the cage listing manufacturer data, capacity, and—if applicable—UN/DOT system markings that must match bottle + cage + base.

- Pallet base (plastic, wood, or steel): Transfers weight to forklifts and racks. Sets load rating, hygiene/corrosion resistance, and durability.

- Top lid & vent: A 6" or 9" screw lid; many use a pressure-vacuum vent to prevent paneling during filling/emptying and temperature swings.

- Bottom valve & discharge: Typically a 2" outlet with a butterfly or ball valve. Common threads are 2" NPT or buttress—confirm before buying adapters. A dust cap protects the face seal.

If you remember one thing: bottle holds, cage protects, pallet moves, lid breathes, valve controls.

Materials and why they matter

- Bottle: High-density polyethylene resists many chemicals. For food or pharma, look for virgin resin and certifications.

- Cage: Galvanized steel for corrosion resistance; some cages are powder-coated.

- Pallet:

- Plastic: Moisture-proof, consistent, good for hygiene.

- Wood: Budget-friendly, repairable, but sensitive to moisture.

- Steel/Hybrid: Heavy-duty, high heat tolerance.

Material choice affects cleanliness, lifespan, and where the tote can be used (food plants, outdoor yards, hazmat, etc.).

Common sizes, weights, and ratings

- Capacities: 275 gal (1,040 L) and 330 gal (1,250 L) are standard.

- Footprint: ~48" × 40" (fits standard pallet racking).

- Ratings: Look for UN/DOT markings for regulated liquids. Stenciling and plates should match the bottle/cage as a system.

Note: UN ratings are system ratings—mixing bottles and cages can void compliance.

Valves, threads, and adapters (avoid surprise leaks)

Most caged IBCs ship with a 2" discharge. The two big thread patterns are:

- 2" NPT: Fine threads.

- 2" Buttress: Coarser, larger pitch.

Always confirm your valve type before ordering camlocks, spigots, or pumps. A $10 wrong adapter can halt production.

Inspection checklist before use or resale

- Bottle: No cracks, bulges, deep gouges, or odor carryover.

- Cage: Straight uprights, intact welds, no severe corrosion.

- Pallet: Intact and flat, not warped; forklift entries sound and unobstructed.

- Valve: Opens/closes smoothly; no drip at the stem or face seal.

- Lid/vent: Gasket present and pliable; vent works if installed.

- Markings: UN/DOT legible if you require regulated transport.

A 30-second valve check can prevent a 300-gallon floor spill.

Applications and compatibility

Caged IBC totes handle water, food ingredients, detergents, inks, adhesives, glycols, and many more. Check the chemical resistance chart for HDPE and the valve elastomer. High-temp fills and strong oxidizers may need specialty bottles, gaskets, or even different container types.

Buying guide: Caged IBC totes for sale

When you see caged IBC totes for sale, compare:

- Condition: New, reconditioned (cleaned/inspected), or previously used for a compatible product.

- Rating: UN/DOT needed? If yes, buy a system with intact matching markings.

- Valve & threads: Match your site’s adapters to avoid downtime.

- Pallet type: Plastic for hygiene/wet areas; wood for budget; steel for heavy abuse.

- Quantity & logistics: Lead times, regional availability, and freight class impact total delivered cost.

Buy to your fittings and your workflow—not the other way around.

Maintenance that extends tote life

- Store out of direct sun where possible; UV ages HDPE.

- Keep valves capped; dust and grit ruin seals.

- Pressure-wash exteriors; follow proper cleaning for interiors.

- Rotate stock by fill date.

FAQs

What is a caged IBC?

A composite tote: HDPE bottle + steel cage + pallet base. The cage protects the bottle and enables stacking and transport.

Is a caged IBC the same as a composite IBC?

Yes. Caged IBC totes and composite IBC totes describe the same bottle-in-cage design.

What valve do I have—NPS or buttress?

Check the threads on the discharge. Fine, tighter threads are often 2" NPS; coarse, deeper threads are typically buttress. If unsure, measure and compare to an adapter chart.

Can I reuse a tote for food after chemicals?

Not recommended. Once a bottle holds a non-food chemical, it should not return to food use. Choose new or properly certified food-grade totes for food and beverage.

How much does a full tote weigh?

As a rule of thumb, 330 gallons of water is ~2,750 lb (plus tote weight ~120–170 lb). Always check your liquid’s density and your floor/rack ratings.

Do I need UN/DOT markings?

If you’re transporting regulated hazardous materials, yes—use a tote with valid UN/DOT markings as a matched system.

Conclusion

A caged IBC tote is simple at heart—bottle, cage, pallet—but the details matter. Pick the right capacity, rating, pallet base, and valve thread so your fittings work and your product stays safe. Verify markings, train handling, and document prior contents if you plan to reuse. Do that, and you’ll get a durable, compliant container that moves liquids efficiently with fewer surprises.