What Wood Are Pallets Made Of?

A practical guide to pallet lumber—species, treatments, and how to choose the right option for your operation.

Key Takeaways

- Hardwood and softwood both work. Species choice usually follows availability, strength needs, and cost—performance depends more on design and grade than the exact wood.

- Design drives performance. Board thickness/spacing, stringer vs. block, and entry style (2-way/4-way) have a bigger impact than species alone.

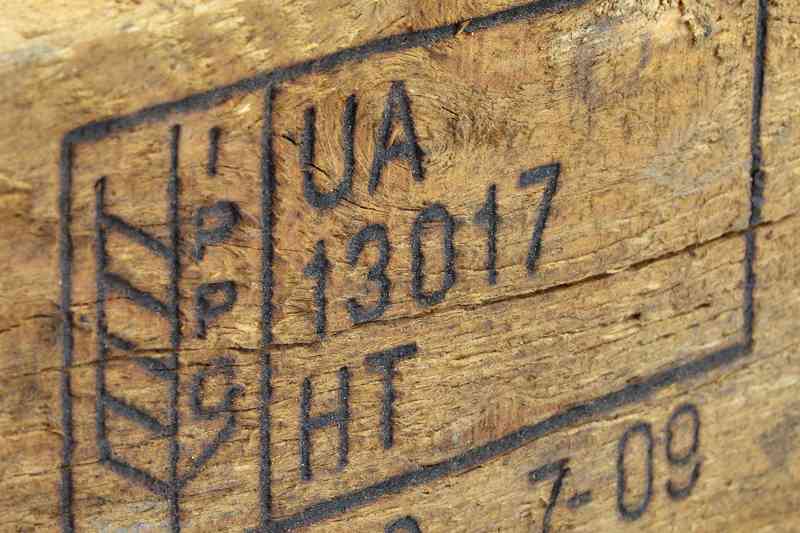

- Heat treatment matters for export. Specify ISPM-15 HT and verify stamps when pallets will cross international borders.

Pallets are built to move product efficiently, not to showcase a single wood species. Most manufacturers use regionally available lumber that meets strength and cost targets. Understanding the common woods—and how design, treatment, and grading interact—will help you specify the right pallet for the job.

Common Woods Used in Pallets

Softwoods (widely used for new pallets)

Softwoods are popular for new production because they’re light, consistent, and readily available. Here are the typical choices:

- Southern Yellow Pine (SYP): Strong for its weight; abundant in the U.S. South.

- Spruce-Pine-Fir (SPF): Light and workable; common across North America.

- Douglas-fir / Hem-fir: Good stiffness; often chosen for stringers or deck boards.

Together, these softwoods support high-volume builds with predictable fastener holding and easy heat treatment (HT) compliance.

Hardwoods (common in recycled/used markets)

Hardwoods show up frequently in repaired or remanufactured pallets because they’re durable and available from regional sawmills. Typical species include:

- Oak, Maple, Poplar, Ash, Beech, Gum: Tough, wear-resistant “mixed hardwoods.”

- Cottonwood & Aspen: Lighter hardwoods that still meet many general-duty needs.

In practice, “mixed hardwood” components balance cost with longevity in multi-cycle use.

Pallet Woods Overview

| Category | Typical Species | Most Common In | What It’s Good At |

|---|---|---|---|

| Softwood | Spruce-Pine-Fir (SPF) | New pallets, high-volume builds | Lightweight, easy nailing, consistent supply |

| Softwood | Southern Yellow Pine (SYP) | New pallets, Southeast U.S. | Strong for weight, good fastener holding |

| Softwood | Douglas-fir / Hem-fir | Stringers/deck in new builds | Stiffness, dimensional stability |

| Hardwood | Mixed Hardwood (Oak, Maple, Ash, Beech, etc.) | Repaired & used markets | Durability, wear resistance over many cycles |

| Hardwood (lighter) | Poplar / Cottonwood / Aspen | Regional new & used components | Lighter hardwood option; cost-effective |

| Any (mixed) | Mixed Softwood/Hardwood | Used, Grade A/B programs | Balances cost and longevity; circular use |

Species vs. Design: What Actually Drives Performance

Species influences weight and nail retention, but design and grade often matter more. Consider board thickness/spacing, stringer or block style, and 2-way vs. 4-way entry to match the pallet to real-world handling.

The takeaway: a well-designed softwood pallet can outperform a poorly designed hardwood pallet.

New vs. Used/Remanufactured Pallets

Both new and remanufactured pallets can be the right choice—your application decides. At a glance:

- New pallets: Often softwood or mixed softwood with tight tolerances and easy HT stamping for export.

- Used/remanufactured pallets: Mixed hardwood/softwood parts, graded (A/B) for condition and value.

If consistency and appearance are critical, new may fit best; for cost and sustainability, a graded used option can excel.

ISPM-15 & Other Treatments

Most international shipments require ISPM-15 compliance, which is straightforward to request from suppliers. Key points include:

- ISPM-15 Heat Treatment (HT): Kiln-heating to eliminate pests; look for the IPPC HT stamp.

- Fumigation (MB): Largely phased down and often avoided due to environmental/health concerns.

In short, specify HT for export and confirm stamp visibility on components; chemical treatments are rarely needed for dry goods.

Choosing the Right Wood for Your Use Case

Match the pallet to your load, equipment, and route rather than chasing a specific species. Typical scenarios look like this:

- High-throughput/automation: New softwood (SPF/SYP) with tight tolerances and HT.

- General warehousing/cost control: Graded used or remanufactured pallets (mixed species).

- Heavy/abrasive loads: Thicker deck boards, extra stringer support, or hardwood components.

By aligning design, grade, and treatment with the job, you’ll get reliable performance at the right price point.

Conclusion

Pallets succeed because they’re engineered systems—not because they’re oak, pine, or anything in between. Softwood or hardwood can both work exceptionally well when matched to the design, grade, and treatment your operation requires. Specify what matters—dimensions, entry type, board thickness, grade, and HT—and you’ll get pallets that move product safely, consistently, and sustainably.